The Ductile Cast iron Manhole Covers and frames and gully and grate which are produced by our company with below advantages:

Security, prevent the cover being stolen

No noise.

High load-bearing

corrosion resistance

Safe

1. According to BS EN124:1994,

2. The material grade: GGG500/7,

3. Coating: black bitumen, epoxy powder.

4. A15, B125, C250, D400, E600 and F900

Ductile iron manhole covers and gully grates are divided into the following classes:

A15, B125, C250, D400, E600 and F900.

1: (class A15 minimum) Test 1.5 metric ton

Areas which can only be used by pedestrians and pedal cyclists.

2: (class B125 minimum) Test 12.5 metric ton

Footways, pedestrian areas and comparable areas, car parks or car parking decks.

3: (class C250 minimum) Test 25 metric ton

For gully tops installed in the area kerbside channels of roads which when measured from the kerb edge, extend a maximum of 0.5m into the carriageway and a maximum of 0.2m into the footway.

4: (class D400 minimum) Test 40 metric ton

Carriageway of roads (including pedestrian street), hard shoulders and parking areas, for all types of road vehicles.

5: (class E600 minimum) Test 60 metric ton

Areas imposing particularly high wheel loads, e.g. docks, aircraft pavements.

6: (class F900 minimum) Test 90 metric ton

Areas imposing particularly high wheel loads, e.g. docks, aircraft pavements.

7: Square/ Round/Rectangle Ductile Iron Manhole Cover and Frame

Heavy Duty Square and Rectangular Manhole cover and frame.

Medium Duty Square and Rectangular manhole cover and frame.

Light Duty Square and Rectangular manhole cover and frame.

Circular cover with circular frame

Circular cover with square frame

Channel grating, double layer cover and frame

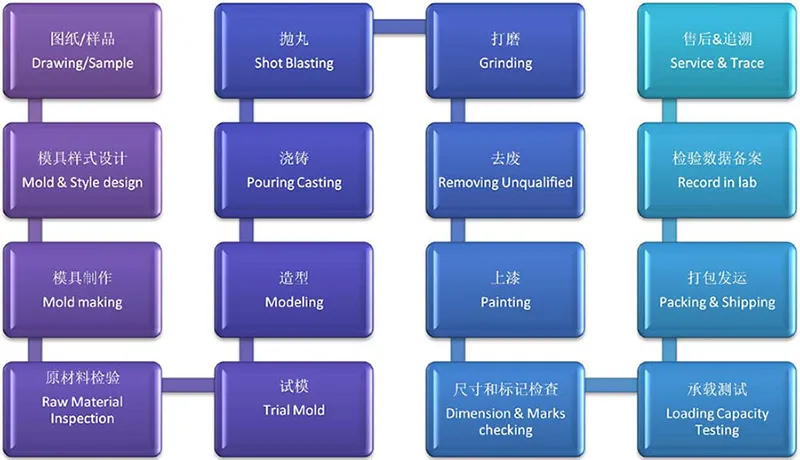

Manhole covers production process

Capacity load testing and inspection before delivery and loading containers